Manufacturing companies today face unprecedented pressure to scale production while maintaining quality and controlling costs. Traditional manufacturing methods often struggle to meet the flexibility required for modern production demands.

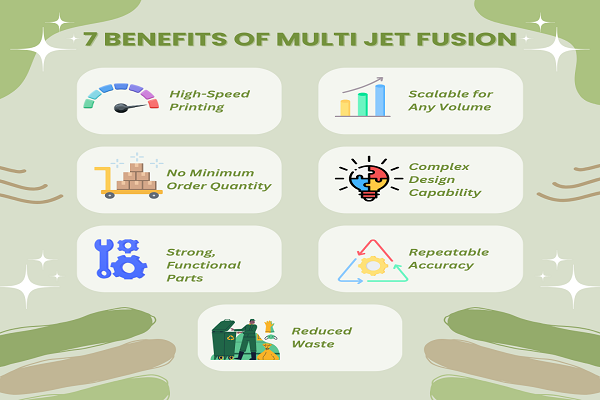

MJF 3D printing has emerged as a game-changing solution, enabling manufacturers to produce high-quality parts at scale without the traditional constraints of tooling and setup costs. This technology combines speed, precision, and cost-effectiveness in ways that weren’t possible just a few years ago.

Companies are discovering that this advanced printing method can transform their entire production workflow, enabling them to respond quickly to market demands while maintaining competitive pricing and superior quality standards.

Table of Contents

Understanding Multi Jet Fusion Technology

Modern manufacturers need production methods that can adapt quickly to changing demands. The multi jet fusion process represents a significant advancement in additive manufacturing, using thermal inkjet arrays to selectively fuse nylon powder layers with remarkable precision.

How Multi Jet Fusion Works

The process begins with a thin layer of nylon powder spread across the build platform. Specialized inkjet heads then deposit fusing and detailing agents onto specific areas of the powder bed. An infrared energy source heats the treated areas, causing the powder particles to fuse and form solid parts.

This method differs significantly from traditional laser-based systems. Instead of tracing each part with a laser point, the entire layer fuses simultaneously, dramatically reducing production time. The unfused powder acts as natural support material, eliminating the need for additional support structures.

Key Technology Components

HP 3D printer systems utilize proprietary thermal inkjet technology originally developed for traditional printing applications. The fusing agent absorbs infrared energy and transfers heat to the powder, while the detailing agent helps control the fusion process for crisp, detailed edges.

The powder bed fusion process operates at optimal temperatures to ensure consistent part quality. Advanced cooling systems maintain precise temperature control throughout the build process, preventing warping and ensuring dimensional accuracy across all parts in the build chamber.

Production Speed and Efficiency Advantages

Speed remains one of the most compelling benefits for manufacturers considering this technology. MJF printing can produce parts up to 10 times faster than traditional laser-based systems, dramatically reducing lead times for production parts.

Batch Production Capabilities

The ability to nest multiple parts within a single build job maximizes production efficiency. Unlike traditional manufacturing methods that require individual setups for each part, MJF allows hundreds of components to be produced simultaneously in a single build cycle.

Build volumes can accommodate various part sizes, from small intricate components to larger structural parts. This flexibility means manufacturers can mix different products in the same build, optimizing machine utilization and reducing per-part costs.

Continuous Production Workflows

Advanced MJF printer systems feature integrated cooling and post-processing stations that enable continuous operation. While one build chamber cools, another can begin printing, creating an efficient production pipeline that maximizes throughput.

The high rate of powder reusability, typically around 80%, further enhances efficiency by reducing material waste and lowering operational costs. This sustainable approach to production aligns with modern manufacturing requirements for environmental responsibility.

Cost-Effectiveness for Large-Scale Manufacturing

Traditional manufacturing methods often require significant upfront investments in tooling and setup costs. MJF 3D printing eliminates these barriers, allowing manufacturers to scale production without proportional increases in fixed costs.

Reduced Tooling Requirements

The elimination of expensive molds, dies, and fixtures represents substantial cost savings for manufacturers. Parts can be modified or updated without retooling, enabling rapid iteration and customization without affecting production economics.

This flexibility proves particularly valuable for manufacturers dealing with frequent design changes or customer-specific modifications. The ability to implement changes quickly without stopping production lines provides significant competitive advantages in fast-moving markets.

Quality and Consistency Benefits

Manufacturing at scale requires consistent quality across all production runs. MJF printing delivers isotropic mechanical properties, meaning parts exhibit uniform strength in all directions, unlike traditional layered manufacturing methods.

Dimensional Accuracy and Precision

The technology consistently achieves tolerances around ±0.2% with a minimum threshold of ±0.2mm. This precision enables manufacturers to produce parts that meet strict specifications without secondary machining operations in many applications.

Surface finish quality rivals that of injection-molded parts, with smooth surfaces that often require minimal post-processing. The controlled fusion process creates dense, non-porous parts with excellent mechanical properties suitable for end-use applications.

Repeatability Across Production Runs

Process parameters can be precisely controlled and repeated, ensuring consistent quality across multiple production batches. This repeatability is crucial for manufacturers who need to maintain quality standards while scaling production volumes.

The technology’s ability to maintain consistent heating across the build area enhances repeatability, particularly beneficial for series production runs where every part must meet identical specifications.

This consistency reduces quality control costs and minimizes the risk of defective parts reaching customers.

Material Versatility and Applications

The range of materials available for MJF printing continues to expand, providing manufacturers with options for diverse applications. Nylon remains the primary material, offering excellent mechanical properties for functional parts.

Engineering-Grade Materials

High-performance nylon variants provide enhanced strength, chemical resistance, and thermal stability. These materials enable manufacturers to produce parts that replace traditionally manufactured components without compromising performance.

Flexible materials like thermoplastic polyurethane (TPU) expand application possibilities into areas requiring elasticity and impact resistance. This versatility allows manufacturers to consolidate multiple material types into single production runs.

Industry-Specific Applications

Automotive manufacturers use MJF for producing lightweight, durable components that meet strict performance requirements. The technology’s ability to create complex geometries enables part consolidation, reducing assembly complexity and weight.

Healthcare applications benefit from the technology’s biocompatible material options and ability to produce customized parts efficiently. The combination of speed and precision makes it ideal for medical device manufacturing.

These diverse applications demonstrate the technology’s potential to transform manufacturing across multiple industries.

Scaling Production with Multi Jet Fusion

The transition from prototype to production becomes seamless with MJF technology. Manufacturers can begin with small batches and gradually increase production volumes without significant changes to their process or equipment.

Flexible Production Volumes

Unlike traditional manufacturing methods that require minimum production quantities to be economical, MJF remains cost-effective even for smaller batches. This flexibility enables manufacturers to respond quickly to market demands without overproducing.

The technology scales efficiently from hundreds to thousands of parts per month, providing growth paths that align with business expansion. Production capacity can be increased by adding equipment or extending operating hours without fundamental process changes.

Common Questions About Multi Jet Fusion

Is MJF stronger than FDM?

MJF printers create stronger prints than FDM printers, though FDM works with more material types including rigid and flexible thermoplastics. MJF focuses on nylon, polypropylene, and TPU materials.

How accurate is Multi Jet Fusion?

MJF consistently achieves tolerances around ±0.2% and maintains a minimum threshold of ±0.2mm, positioning it as preferred for high-precision components demanding detailed, reliable parts.

What’s the maximum build size for MJF?

Build volumes vary by system, with industrial machines typically accommodating dimensions up to 380 x 284 x 380mm, suitable for most production applications.

Making the Most of Your Manufacturing Future

Multi Jet Fusion represents a fundamental shift toward more responsive, efficient production methods. The combination of speed, quality, and cost-effectiveness positions this technology as a cornerstone of modern manufacturing strategies.

Companies that embrace MJF technology today are positioning themselves for tomorrow’s competitive landscape. The ability to scale production efficiently while maintaining quality standards will become increasingly important as markets demand faster response times and greater customization.

The most exciting aspect isn’t just what MJF can do today, but how it’s continuing to evolve for manufacturing innovation that we’re only beginning to explore.