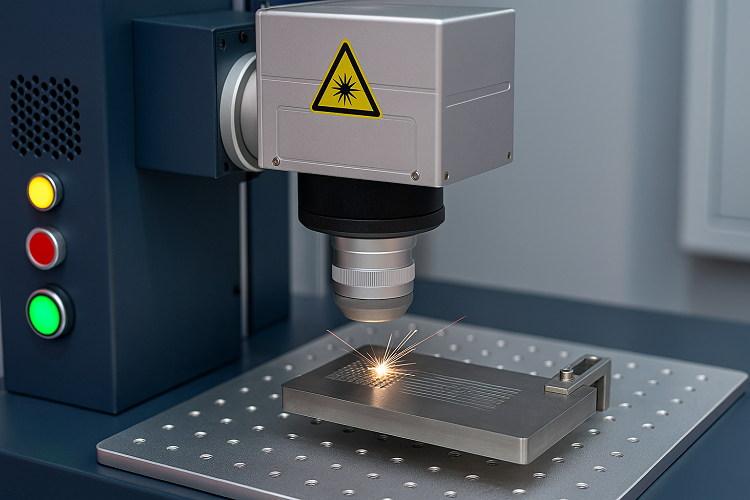

The engraving industry has been transformed with the introduction of 3D laser marking technology which offers remarkable precision, efficiency, and innovation. In this article, I will discuss the 3D laser marking machines, their uses in different industries, and share tips on how to select the most appropriate equipment for your engraving tasks. While examining the workings, advantages, and developments of these machines, we aim to highlight their potential to lead the engraving industry in precision and accuracy.

For more in-depth information, you should view the 3D Laser Marking Machine – UDMachine.

Table of Contents

What is a 3D Laser Marking Machine and How Does it Work?

Understanding the Basics of Laser Marking

Permanent marks can be made on different surfaces through a process known as laser marking, which etches or engraves with a laser beam. Unlike traditional methods, laser marking does not require contact with the material, hence alleviating wear and tear, and maintaining the item’s integrity. The fundamental process is enhanced with the use of a 3D laser marking machine that marks in three dimensions with more complex designs and deeper engravings than 2D counterparts.

In What Ways Does 3D Laser Technology Improve Marking?

3D laser technology enhances marking sophistication beyond the scope of traditional systems. It enables the manipulation of the laser beam in ways that makes marking curved surfaces or detailing uneven textures possible. With a high precision 3D galvo control system, the machine is capable of dynamically changing the focal point of the laser beam and thus, challenging surfaces can be intricately marked with varying degrees of difficulty. This guarantees sharp and clear images enduring varying degrees of surface curvature.

What Are the Core Components of a Laser Engraving Machine?

A 3D laser engraving machine is made up of distinct parts that function together to achieve accurate marking. These parts include the laser beam generator and the control system that manages the beam’s path. Moreover, the machine uses imported core components to guarantee precision and efficiency. One’s choice of laser source, whether a fiber laser or a UV laser, greatly affects how the machine performs on materials like aluminum and glass. Knowing these components is important in choosing the most fitting 3D laser marking machine for particular engraving tasks.

What Are the Advantages of Using a 3D Laser Engraving Machine?

Precision and Efficiency in Marking

Perhaps one of the most defining benefits 3D laser engraving machines is their precision in marking is unparalleled. This technology allows for intricate and complex deep engravings to be made while retaining the level of detail required. In addition, the steps taken to automate the 3D laser marking processes improve efficiency, streamlining workflows, reducing production time, and increasing throughput. Such operational efficiency ensures reduced engraving turnaround times while decreasing overall production costs. This makes the technology very appealing to businesses looking to optimize engraving operations.

Engravings of Exceptional Quality on Multiple Surfaces

3D laser marking machines are able to engrave on a wide variety of materials such as metals, plastics, and even glass, which broadens their applications and versatility. The ability to mark on curved surfaces opens new frontiers for industries like jewelry designing, which need detailed, customized engraving. The precision offered by 3D lasers makes it possible to engrave elaborate patterns, which enhances the aesthetic appeal of jewelry. Moreover, the adaptability of the machine to different surface conditions guarantees that the quality of engraving remains uniform irrespective of the engraving material used.

Integration with Sophisticated Marking Software

The marking and engraving industry has experienced change with the incorporation of 3D laser marking systems into specific software and control technologies. This software not only interfaces with the engraving machine but also permits designer-directed scheduling which helps in managing marking operations. Advanced marking software provides the flexibility of real-time corrections or modifications during the engraving process, thus ensuring design accuracy and enhancing quality. In addition, the software broadens its scope to various materials which makes the machine useful in multiple industries.

What Industries Benefit from 3D Laser Marking Systems?

Applications in Manufacturing and Production

The applications of 3D laser marking systems are prominently visible across various sectors within the manufacturing and production industries. They are primarily employed for marking vital components with serial numbers, barcodes, and logos. The accuracy provided by 3D laser marking guarantees the markings will withstand significant wear and tear, thereby safeguarding component traceability and quality assurance. These machines are also advantageous to companies that have high-speed production lines as they increase operational efficiency and productivity due to the automation features available.

Use cases in the jewelry and craft industries.

There is an ever-growing demand for intricate designs in the jewelry and craft industry. Artisans can now etch designs on metals, glass, and other surfaces with exceptional precision courtesy of 3D laser marking technology. This technology offers an artistic touch that traditional methods struggle to achieve by enabling detailed engravings on curved surfaces. It also allows designers to modify their work during the testing stages through rapid design prototyping, thus enhancing the overall creativity in the production process.

3D Laser Marking in Medical and Aerospace Fields

In the medical and aerospace domains, components require meticulous marking with utmost precision and dependability. For inscribing intricate identifiers on surgical tools, lexis, electronic components, and structural elements, 3D laser marking machines are indispensable. The accuracy offered by the laser guarantees the preservation of crucial information over the entire lifespan of the product. In addition, the automated nature of these marking systems, coupled with their efficient operation, minimizes the human factor, an important aspect in industries where safety and adherence to standards are critical.

How to Choose the Right 3D Laser Marking Machine?

Key Parameters to Consider for Effectiveness

Choosing a 3D laser marking machine requires specific parameters for consideration to meet the intended marking purpose. Different models may work optimally with certain materials, so the application and material considerations are primary. Also, marking speed is critical; businesses require high throughput without compromising quality. Consider how the machine will handle intricacy in design as well as the depth of engraving needed, since these factors will determine the machine’s suitability for given workload tasks.

Comparing Different Laser Technologies: Fiber vs. UV Laser

The choice of fiber laser versus UV laser technologies will have a considerable impact on the 3D laser marking machine’s performance. Fiber laser systems are more productive with metals as they engrave deeper, while UV lasers are better at marking on plastic and glass as they do not scorch the surface. It is important to note the differences in laser technologies as each type has advantages and disadvantages concerning specific engraving requirements.

Assessing Marking Speed and Surface Compatibility

In the context of a 3D laser marking machine, marking speed is central to operational efficiency. Performance evaluation should not only measure how fast the machine completes tasks but also scrutinize the quality of work produced. Furthermore, evaluating the surface compatibility of the machine is important for achieving effective results on different materials. Understanding both marking speed and surface versatility enables companies to choose an optimal 3D laser marking machine tailored to their production needs and requirements.

What Are the Latest Innovations in 3D Laser Marking Technology?

Overview of Dynamic Laser Marking Systems

Recent advancements in 3D laser marking technology include dynamic laser marking systems that respond to changes during the engraving process. Now, the machine can adaptively change the laser’s focus and power level to the surface details and how intricate the design is. Such systems improve the quality of engravings while minimizing production errors, providing state-of-the-art marking technology.

improvements in software for management and accuracy

The development of specific software and control systems for 3D laser marking machines has greatly impacted their accuracy and functionality. Enhanced software includes functions that facilitate design work, engraving quality assessment monitoring, and laser control management including parameter presets as well as manual adjustments. These features are advantageous to operators and increase precision while expediting work due to less time needed to master sophisticated equipment.

Developments and Innovations in 3D Engraving and Marking Systems

Advancements in the hardware and software capabilities of 3D laser marking technologies will expand their current applications, which is why the future appears promising. There are expectations that the artificial intelligence integration into marketing systems for predictive analysis will automate engraving optimization and simplify user interaction, further expanding their application. These technologies will ensure that the 3D laser marking machines solidify their engraving position across industries.